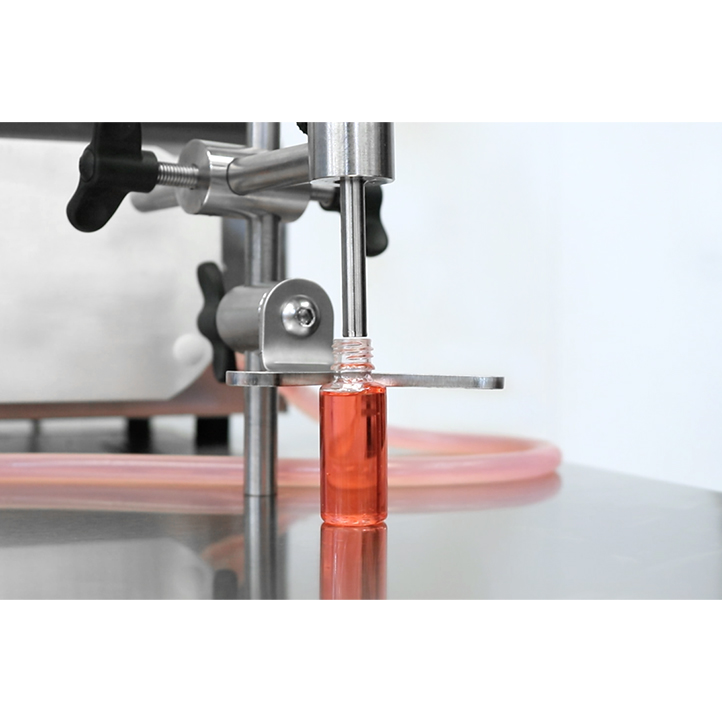

K-One Precise and versatile dosing machine, peristaltic pump suitable for filling liquid products

Developed by CDA engineers from the best materials on the market, the K-One peristaltic filling pump is appreciated for its high precision and versatility.

CDA’s K-One peristaltic pump can be used in automatic or semi-automatic dosing machines, both on a complete packaging line and in “manual” use for packaging small production quantities.

The peristaltic technology offers many advantages:

- the product does not come into contact with the pump,

- easy and fast hose change,

- reduced cleaning time,

- correction of the set dose calculated automatically after entering the dose actually obtained during the adjustment,

- waste-free start-up via priming button,

- fast cleaning without product loss (reverse rotation).

The risks of cross-contamination are drastically reduced.

It is the ideal system for packaging “hygiene, health, agri-food” products such as e-liquid, natural flavours, essential oils, etc.

The K-One filler is controlled by an intuitive touch screen for easy handling, visualization and rapid modification of all control parameters.

This filling machine can be complemented by a CDA screwer/capper and a labeller (in particular a machine from the semi-automatic range).

See all our fillers in action on our youtube channel.

Fluid

- Automatic or semi-automatic mode

- No contact with the pump for a fast product change and an easier cleaning process

- Easy to use and easy settings

-

Production rateup to 1500 products/hour for 10mL

-

FunctionsVolume, Speed, Acceleration, Deceleration, Reaspiration

-

Special featuresBatch Production in semi-automatic mode - Memory 96 lines

E-liquids

Food processing industry

Cosmetics industry

Chemical industry

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries